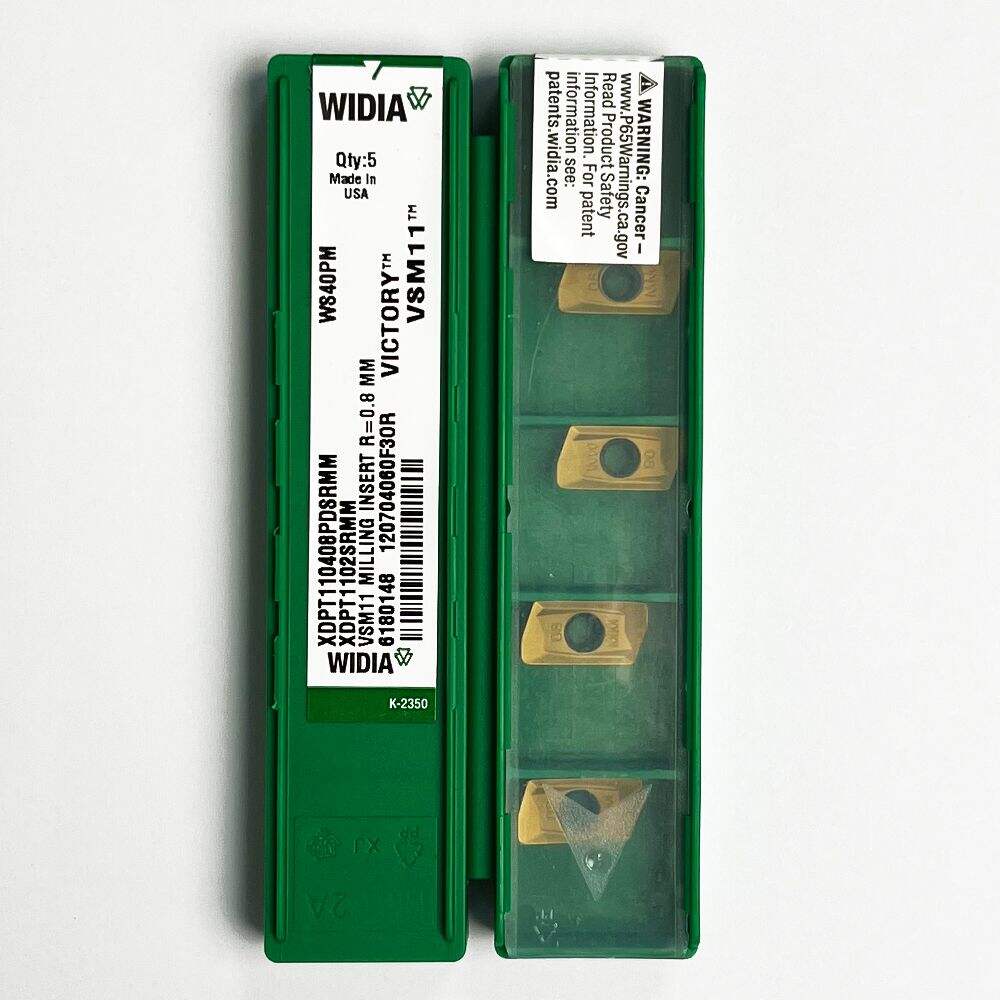

cijena: 62 RMB 9.5 dolara

cijena: 89 JPY 13.5 USD

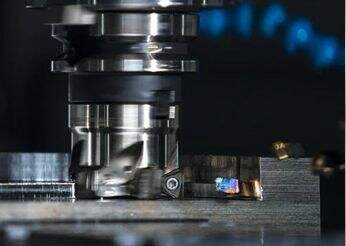

Izrada matrice za utiskivanje zahtijeva vrlo specijalizirane vještine obrade metala - izravan rad u lijevanom željezu, nodularnom željezu i kaljenom čeliku, kao i napredne tehnike rezanja. To zahtijeva optimizaciju vašeg procesa strojne obrade kako biste smanjili troškove strojne obrade i vrijeme isporuke.

Oprema za bušenje nafte, tijelo stabla, vješalica za cijevi, ventil, trn, utor za brtveni prsten API, naširoko se koristi u proizvodnji strojeva za naftu, za različite dijelove za odabir različitih vrsta CNC alata.

disk s lopaticama, središnja krilna kutija, pilon motora, vodilica diska ventilatora, rotor, potporna greda stajnog trapa, glavna oprema, zglobna osovina nosača motora, vodeći rub letvice, vodilica, klizni ventil, potisni zglob, kućište turbine, turbinski disk, okomito repno krilo, rebro kutije

Prirubnice za opremu za vjetroelektrane i ostalo trebaju razne alate za bušenje, okretanje, glodanje, mi vam pružamo vitalne alate. Naširoko se koristi u raznim prirubnicama, školjkama, nosačima i drugim proizvodima za energiju vjetra.

Brodogradnja, oprema za proizvodnju električne energije, industrija reduktora, mnoga oprema treba proizvodnju CNC obradnog centra, ključna je potrošnja alata.

1. Prvo, ima jaku otpornost na trošenje i tlačnu čvrstoću, 2. Možemo smanjiti učestalost promjena alata u proizvodnom procesu, možemo razumno uštedjeti svo vrijeme proizvodnje. 3. Preciznost CNC oštrice je vrlo visoka, tako da može poboljšati radnu učinkovitost i njegovu dugoročnu upotrebu

1. Može biti prikladan za bušenje složenijih materijala, može odabrati veću brzinu rezanja, može bušiti tvrđe materijale,2. Odaberite oštrice od legure visokih performansi namijenjene svrdlima od legure kako biste učinkovito smanjili lom noža i održali dobru otpornost na habanje. 3. Višeslojni geometrijski rezni rub za poboljšanje performansi pražnjenja i održavanje malog otpora rezanju. 4. Uz uobičajeno korištenu ručku pod pravim kutom, postoji niz vrsta ručki, prikladnih za razne strojeve za bušenje.

1. Ima dobru stabilnu reznu izvedbu, krutost alata, visoku preciznost, može se rezati velikom brzinom i snažno rezanje. Serijalizacija alata, standardizacija i modularizacija Serijalizacija alata, standardizacija i modularizacija pogoduju programiranju, upravljanju alatima i smanjenju troškova. 3 Alat (oštrica) ima dobru izmjenjivost i može brzo promijeniti alat. Alat se može automatski i brzo zamijeniti kako bi se skratilo pomoćno vrijeme. 4 alat s visoko preciznim nadzorom alata prikladan je za obradu visoko preciznih izradaka,

1. Alat ima dug vijek trajanja, što štedi vrijeme potrebno za česte izmjene alata i noževa 2. Pogodan za brzu suhu obradu, bez tekućine za rezanje, zaštita okoliša i pouzdanost 3. Veličina obratka je stabilna nakon obrade ,koji može zamijeniti postupak mljevenja radi poboljšanja učinkovitosti 4.Može obraditi razne kompozitne materijale koje je teško obraditi

Tvrtka je uspostavila dugoročne i stabilne odnose suradnje s brojnim trgovcima i agentima. Raznolikost je potpuna, a cijena prihvatljiva. Veliki kredit, pridržavanje ugovora, osiguranje kvalitete proizvoda, s različitim radnim karakteristikama i načelom male zarade i brze prodaje, osvojili su povjerenje kupaca.

Surađujte s nama

Vrlo je učinkovit i može zadovoljiti moje potrebe. Raznolikost proizvoda je također vrlo bogata, a cijena je također vrlo niska. Imamo sretnu suradnju

Kvaliteta je vrlo dobra, je li original originalan, usluga je također vrlo entuzijastična, uvijek ćemo održavati suradnju

Učinite svoju kupnju ugodnijom. Transparentne cijene olakšavaju kupnju. Pošten je i vrijedan povjerenja, usmjeren na kupca, kako bi kupcima pružio savršenu uslugu

Pomozite vam da eliminirate neplanirane zastoje, smanjite golema ulaganja koja trošite na opremu i obuku operatera.

Grad Xuzhou, provincija JiangSu, Kina.