عندما يتحدث الأشخاص عن أدوات القطع CNC (التحكم العددي بواسطة الحاسوب)، فإنهم عادةً ما يشيرون إلى أحد فئتين رئيسيتين: الأدوات الصلبة والأدوات القابلة للإدراج. تُستخدم كلتا الأداتين داخل الآلات أثناء عملية قطع وتشكيل المواد من قِبَل هوازهيتشون . دعنا نساعدك في معرفة هذه الأدوات وكيفية اختلاف كل منها عن الأخرى.

ما هي أدوات القطع CNC الصلبة؟

تُصنع أدوات القطع CNC باستخدام قطعة واحدة من المادة الصلبة. أدوات CNC عادة ما يكون نوعًا من الصلب المعالج حراريًا، مثل الكاربايد أو الصلب السريع. يتم تصميم نهاية الأداة بطريقة مثيرة للاهتمام بحيث يمكنها قطع المواد المميزة. نظرًا لأن هذه الأدوات تُصنع من قطعة واحدة، فهي قوية بما يكفي لتحمل المهام الثقيلة. هذا يجعلها مثالية لقطع المواد الصلبة مثل التيتانيوم والصلب غير القابل للصدأ، والتي تُستخدم بشكل شائع في مختلف الصناعات. حسنًا، بما أن الأداة نفسها صلبة، فمن المحتمل ألا تنكسر أثناء قطع هذه المواد القاسية.

ما هي أدوات القطع CNC ذات الإدراج

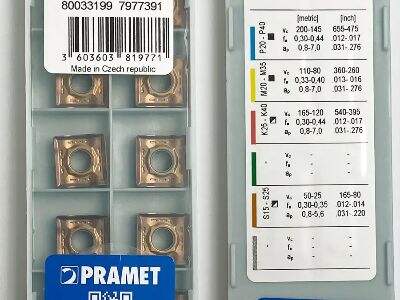

تعد أدوات قطع الملف الشخصي CNC ذات الإدراج أكثر تعقيدًا قليلاً. تتكون من جزئين، جسم الأداة والإدراج. وعلى الرغم من أنه يمكن أن يختلف من أداة إلى أخرى، فإن معظم أجسام الأدوات تُصنع من معادن قوية جدًا مثل الصلب حتى تظل ثابتة أثناء الاستخدام. الإدراج هو مكون صغير ينقر في مكانه داخل جسم الأداة. هذا إدراج قطع الكاربايد المقعد هو الجزء الذي يقوم بالقطع. واحدة من الأشياء الرائعة حول أدوات المقعد هي أنه بمجرد أن يصبح المقعد مبلغاً أو مستهلكاً، يمكنك ببساطة إخراجه ووضع واحد جديد. هذا يعني أنك لا تحتاج إلى استبدال الأداة بأكملها، مما يحافظ على وقتك ومالك.

المزايا والعيوب لأدوات التقطيع الصلبة والمقعد

لكل من الأدوات الصلبة وأدوات المقعد المستخدمة في التحكم العددي (CNC) مزايا وعيوب معينة. لنلقِ نظرة أقرب على بعض هذه المزايا والعيوب.

أدوات القطع الصلبة:

إيجابيات: تُعرف الأدوات الصلبة بأنها قوية ومتينة للغاية. وهذا يجعلها مثالية لقطع المواد الصعبة دون الانحناء أو الكسر. كما أنها سهلة النموذج نسبيًا، حيث يتطلب الأمر فقط تشكيل طرف الأداة ثم تكون جاهزًا للقطع.

النقاط السلبية: يمكن أن تكون الأدوات الصلبة أكثر تكلفة من الأدوات القابلة للإدراج. بما أنها مصنوعة من قطعة واحدة، إذا تم استخدام النهاية بشكل كبير بسبب القطع، فإما أن عليك إنفاق الوقت لشحذها مرة أخرى إلى نقطة حادة أو شراء أداة جديدة بالكامل، مما يمكن أن يزيد من التكلفة.

أدوات القطع القابلة للإدراج:

المزايا: الأدوات القابلة للإدراج مرنة نسبيًا. بما أنه يمكنك تبديل الإدراج بسهولة، يمكنك استخدام أنواع مختلفة من الإدراج لأعمال مختلفة. إذن إدراج كربوني دائري يمكن أن يكون لديك إدراج واحد للقطع الخشن، وإدراج آخر للقطع الناعمة. هذا النوع من المرونة يمكن أن يعني عملًا أكثر كفاءة من جانبك، وعادة ما تكون أكثر اقتصاداً من الأدوات الصلبة، وهي خيار جيد آخر للأشخاص الذين يبحثون عن توفير المال.

النقاط السلبية: أحد العيوب المحتملة للأدوات القابلة للإدراج هو أنها قد لا تكون قوية مثل الأدوات الصلبة. يرتبط جسم الأداة مع الإدراج في مفصل، مما يمكن أن يقلل من صلابة الأداة. هذا قد يجعلها أقل دقة في القطع وأقل متانة مقارنة بالأدوات الصلبة.

اختيار الأداة المناسبة لقطع CNC

بالطبع، قد تسأل، لكن ما هي أداة قطع CNC المناسبة لك؟ الإجابة تعتمد حقًا على ما تحتاج إلى القيام به! إليك العوامل الرئيسية التي يجب أن تأخذها في الاعتبار عند اتخاذ قرارك:

المادة: فكر فيما تقوم بقصه. على سبيل المثال، إذا كنت تقوم بالتصنيع باستخدام مواد صلبة للغاية مثل التيتانيوم أو الإينوكيل، فقد يكون من الأفضل استخدام أداة قطع صلبة لأنها تستطيع تحمل هذه الأعمال الشاقة. ومع ذلك، إذا كانت عمليات التصنيع الخاصة بك تتضمن مواد ناعمة مثل الألومنيوم أو البلاستيك، فقد تكون الأدوات القابلة للإدراج أكثر ملاءمة، حيث ستقوم بالمهمة بشكل كافٍ.

التطبيق: خذ لحظة للتفكير في نوع القطع الذي تحتاج إلى القيام به. إذا كنت ترغب في الحصول على سطح ناعم جدًا، فقد يكون أداة ذات شفرة إدراج هي الخيار الأفضل. ولكن إذا كنت تريد عبور كمية كبيرة من المادة بسرعة، فستحتاج على الأرجح إلى أداة معينة مناسبة لهذا النوع من العمل.

التكلفة: ماذا ستدفع؟ ومع ذلك، كما ذكرنا سابقًا، فإن أدوات القطع القابلة للإدراج تكون بشكل عام أرخص من الأدوات الصلبة. قد تكون أداة الإدراج خيارًا حكيمًا إذا كنت تعمل ضمن ميزانية وتريد توفير بعض المال.

عمر الأداة: اأخذ في الاعتبار المدة التي تحتاج أن تدومها الأداة. الأداة الصلبة أكثر متانة ويمكنها تحمل المزيد من الاستخدام الشاق، لذلك قد تدوم لفترة أطول. لكن إذا كنت تزيل كمية صغيرة من المادة، فقد تدوم أداة الإدراج لفترة كافية لإنهاء عملك دون الحاجة إلى استبدالها.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

KA

KA

UR

UR

BN

BN