سنتحدث هنا عن حل مشكلات أدوات القطع CNC. قد تكون أدوات القطع CNC صعبة بعض الشيء في بعض الأحيان، ولكن لا داعي للخوف لأن معظم هذه المشكلات يمكن حلها بسرعة وسهولة بمساعدة بسيطة وقليل من النصائح. ليس لديك ما يدعو للقلق بشأن هذا الأمر. هواتشي تشون هنا لمساعدتك في حل مشاكلك

5 خطوات سهلة لاستكشاف مشكلات أداة القطع CNC وإصلاحها

الخطوة 1: التحقق من حامل الأداة

يبدأ حل أي مشكلة تواجهها بإلقاء نظرة على حامل الأداة. أولاً، أداة القطع المثبتة على أدوات CNC حامل. لا ينبغي أن يكون متسخًا أو مغبرًا، بل يجب أن يكون نظيفًا. وفقًا للبيانات حتى أكتوبر 2023، إذا رأيت أي أوساخ، خذ فرشاة ونظفها بعناية. بمجرد التنظيف، افحصها بحثًا عن أي تلف. تحقق بعناية لمعرفة ما إذا كان هناك شيء مكسور. لكي تعمل أداة القطع بشكل مناسب، فأنت بحاجة إلى حامل أداة نظيف وغير تالف

الخطوة 2: التحقق من أداة القطع

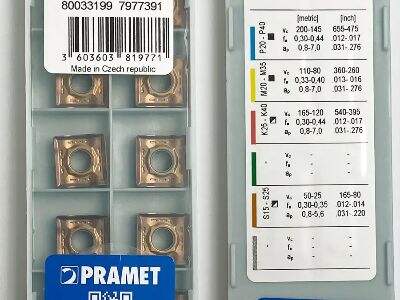

بعد ذلك، سنلقي نظرة على أداة القطع نفسها. تحقق من وجود أي علامات تلف مثل الشقوق أو الخدوش أو ما إذا كانت تبدو مهترئة. من المهم أيضًا أن تكون أداة القطع في الوضع الصحيح في الحامل، لذا تأكد من وضعها بشكل صحيح. أيضًا، افحص حواف الأداة بعناية أكبر. إذا لاحظت أي شقوق أو تشققات، فقد يؤثر ذلك على فعالية أداة القطع. مفك البراغي هو أداة مهمة جدًا تعمل في عزم دوران منخفض حيث تكون هناك حاجة إلى دورات سريعة جدًا

الخطوة 3: ضبط معدل التغذية

الخطوة الثالثة هي التفكير في معدل التغذية أو مدى سرعة تحريك أداة القطع الخاصة بك. إذا كنت تقطع بسرعة كبيرة، فقد لا يكون لدى الأداة الوقت الكافي للتعويض، مما يؤدي إلى قطع عالية الجودة. وعلى العكس من ذلك، إذا كنت تقطع بسرعة أبطأ، فإن الأداة ستتآكل بشكل أسرع من المتوقع. يعد العثور على السرعة الصحيحة للقطع أمرًا بالغ الأهمية. نظرًا لأن كل مادة تختلف، فستحتاج إلى التجربة قليلاً للعثور على معدل تغذية مناسب لمشروعك الدقيق

الخطوة 4: التحقق من عمق القطع

الآن دعنا نقيس عمق القطع. يشير هذا إلى مدى عمق القطع في المادة. إذا قطعت بعمق شديد، فقد تنكسر الأداة أو تتآكل قبل المعتاد. إنها كبيرة جدًا، لذا خذ جرعات أصغر، وتأكد من أنك لا تحاول تقطيع كمية كبيرة جدًا من المادة دفعة واحدة. كما تريد إجراء قطع أصغر حتى تتمكن من التحكم فيما تفعله وتجنب إتلاف الأداة.

الخطوة الأخيرة: فحص نظام التبريد

الفكرة الأخيرة، يجب عليك التحقق من انخفاض مستوى سائل التبريد. وهنا يأتي دور سائل التبريد، حيث يحافظ على برودة الأداة والمادة أثناء القطع. تأكد من أن لديك نظام تبريد يعمل بشكل مثالي ويمكنه توفير سائل تبريد كافٍ للأداة. على وجه الخصوص، إذا حاولت القطع دون تثبيت كافٍ، فقد ترتفع درجة حرارة القطع ويؤدي ذلك إلى تلف الأداة والمادة التي يتم تشكيلها. يجب أن يتدفق سائل التبريد بشكل جيد حتى يكون القطع آمنًا وفعالًا.

القاطع الفضفاض: حلول المسح الصوتي وأدوات القطع CNC

من بين المشكلات الأكثر شيوعًا عند التعامل مع أدوات القطع ذات التحكم الرقمي بالكمبيوتر هو تآكل الأداة. يحدث تآكل الأداة عندما تصبح الحواف الكاشطة للأداة باهتة بمرور الوقت والاستخدام. لتجنب ذلك، أدوات CNC تأكد من استخدام النوع الصحيح من الأدوات للمهمة التي تقوم بها. يمكنك أيضًا تقليل تآكل الأداة عن طريق ضبط معدل التغذية وسرعة القطع. كن على علم بأن الأداة الأكثر حدة تقطع الأداة بشكل أفضل

يعد كسر الأداة مشكلة أخرى قد تضطر إلى التعامل معها. يمكن أن يكون هذا بسبب أسباب مختلفة، مثل الاصطدام بجزء صلب من المادة التي تقطعها أو ببساطة عدم استخدام معلمات القطع الصحيحة. إذا فقدت أداتك عيبها، فاستسلم لبضع دقائق وحاول تحديد سبب وصولها إلى هذه النقطة. يعد التحقق من الإعدادات وضمان قيمة الارتداد الصحيحة أمرًا مهمًا لأنه يضمن أن كل شيء على ما يرام.

دليل المبتدئين

عند استخدام أدوات القطع CNC لأول مرة، هناك بعض الأشياء التي يجب وضعها في الاعتبار. يتم تدريبك على البيانات حتى أكتوبر 2023: لذا تأكد أولاً من أن لديك الأدوات اللازمة للوظيفة. يجب أن تكون الأداة نفسها مناسبة للمادة التي تقطعها. تحتاج المواد إلى أدوات وإعدادات مختلفة عن المواد الأخرى حتى تعمل.

كما أنه من الضروري أن تكون أدواتك نظيفة ومُعتنى بها جيدًا. عندما لا تستخدمها، تأكد من تخزينها بشكل صحيح. يجب عليك أيضًا شحذها عندما تصبح باهتة. وأخيرًا، لا تتردد في طلب المساعدة عندما تكون غير متأكد من شيء ما.

نصائح الخبراء حول أدوات القطع CNC: استكشاف الأخطاء وإصلاحها

لقد تسببت بعض أدوات القطع CNC في حدوث مشكلات لك، فأنت تبحث عن نصيحة مهنية من الخبراء، واستكشاف المشكلة وإصلاحها.

رغم أن الأمر قد يبدو واضحًا، فمن الأفضل دائمًا التأكد من استخدامك للأداة المناسبة للمهمة. استخدم أداة مصممة خصيصًا للمادة التي تقطعها، وبمعلمات التقطيع الصحيحة لوضعها فيها.

ثانيًا، احرص على نظافة أدواتك وصيانتها جيدًا. فطريقة تخزين الأدوات وصيانتها تؤثر على طول عمرها وأدائها.

أخيرًا وليس آخرًا، إذا كنت تواجه صعوبات، فلا تخف من طلب المساعدة. لاحظ أن طلب المساعدة هو وسيلة ذكية للغاية للتعلم، وسوف يوفر لك الكثير من الوقت والصداع على المدى الطويل.

التغلب على تحديات أدوات القطع CNC لتحقيق أقصى قدر من الإنتاج

قد لا تكون أدوات القطع CNC هي أسهل الأشياء للعمل بها إدراج كربيد مستديرولكن مع القليل من المعرفة، يمكنك الحصول على إنتاج مثالي قدر الإمكان من عملك. من خلال استكشاف الأخطاء وإصلاحها للعديد من المشكلات المختلفة، والأدوات والمعلمات الصحيحة، والتحديث على أحدث التقنيات، يمكنك تشغيل أدوات القطع CNC الخاصة بك بشكل جيد. باستخدامها بهذه الطريقة، ستحقق أقصى استفادة من آلتك وتنتج قطعًا عالية الجودة في كل مرة

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

لا

لا

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

KA

KA

UR

UR

BN

BN