Seveda, delo z drevesom je odlično hobijo, ki jo milijoni ljudi rado izvajajo. Omogoča ti, da bistveno ustvarjas in narediš lepe stvari z rokami. Lahko obdeluješ tudi drevo za izdelavo novega nameštja, kot so mize in stolice, ali pa lahko narediš preprosto ptičjo hišico za ptice v svojem dvorišču. Za delo z drevesom je potrebnega veliko strpnosti in truda, saj želiš biti prepričan, da je vse natančno. Vrtni štilet je ena od tistih orodij, s katerimi bi moral vsak delavec z drevesom imeti opremljen. Večina drugih množica vrtačev in vrtal je namenjenega rezanju skozi drevo (na primer: jamka, kamor gre vratna kljukica). Ta članek bo pokrial vse, kar morate vedeti o vrtnih štiletih, kako jih uporabljati, ter bomo sodelili nekaj zabavnih projektov.

Ravne vijake spadajo v določeno kategorijo, ki je ključna v lesarstvu, ker omogočijo natančno rezanje v kosu lesa. Zelo so versatilne, saj so na voljo v različnih velikostih in oblikah. Uporabite ravnih vijakov za enostavno vrtljenje lukov v les, zlasti. Ravna vijaka lahko ustvari ploske lukove s poljubno globino. Mnogi projekti to smatrajo uporabno. Ravne vijake lahko isto tudi uporabite za vrtljenje vitkic in šrpal v les, da se vse pravilno ujema. Lahko jih uporabite tudi za ustvarjanje lukov v debelih kosih lesa, kamor ne more navaden vrteč. To pomeni, da so ravne vijake potrebne vsakemu lesarniku!

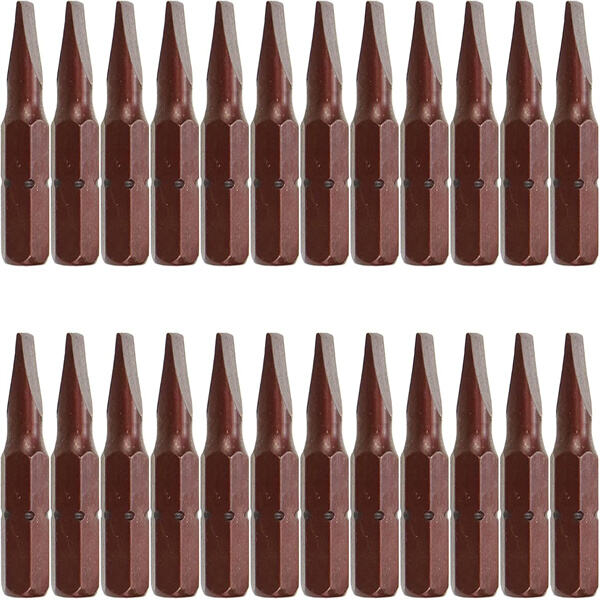

Uporaba vrtoglavka in set vrtoglavk je ena od ključnih korakov za dosego odličnih rezultatov v vaših projektih lesarstva. Pri delu z ravnimi biti je tudi zelo pomembno, da izberete pravi velikostni razmer ravnega bita za opravo dela. Ravne bite so poimenovali tako, ker imajo raven površin na dnu, kar vam omogoča, da izvršite natančne reze. Raven dno omogoča natančno vrteženje, pomemben dejavnik, kadar želite, da vaš projekt izgleda poliran. Ravne bite lahko uporabite tudi za ustvarjanje luknjenj na spremenljivih kotih in globinah, zato vam res daje veliko fleksibilnosti pri oblikovanju načrtov. Natančnost pripomore k lepemu in profesionalnemu izgledu lesnih izdelkov, ki jih izdelujete.

Obstaja veliko vrst ravnih vrtal, ki jih boste našli, ko se odločite za eno. To lahko pomeni, da je težko določiti, katera je najbolj primerna za vaš projekt. Pri izbiri ravnega vrtala morate upoštevati nekaj stvari. Prva stvar je določiti velikost otroke, ki jo želite narediti. Če imate majhen otvor, boste potrebovali majhno ravno vrtalo. Če delate z tvrdim drevesom, trdim vrsto drevesa, je najbolje uporabiti bolj trdno vrtalo. Lahko pridobite različne oblike in velikosti ravnih vrtal, kot so lopaticna vrtala, plovilna vrtala in forstnerja vrtala. Vsak tip ima določeno funkcijo, kar ga dela koristno, da poznate, kaj zahteva vaš projekt.

Ravne vijice, kot katerikoli drug orodje, potrebujejo primerno ohranjanje, da delujejo učinkovito. Če začnete z izkušenimi ravnanimi vijicami in se ošteta postradi, prostost ne bo mogla pravilno rezati skozi slovar in lahko povzroči škodo ter nesreče med vašo delo. Če se začnejo glajšati, morate oktagonske robove svojih ravnih vijic urediti in jih ponovno ošteti. Jih lahko oštejete na oštevalnem kamenju ali pa tudi s pomočjo oštevalne usmeritve, ki vam pomaga doseči pravi kot. Vedno jih tudi držite čistimi in brez ržave. Je pomembno, da jih držite stran od vlage in varno, da se ne poškodujejo ali ne bodo metani okrog.

Zdaleč ne le za vrtetenje lukov, so ravnih steklenic uporabljati v vseh vrstah kreativnih načinov. Drevesne ključnice za sklopce ali vrata so še en primer, prav tako pa lahko pripomorejo k edinstvenemu slogu vaše nameštja. Ravnih steklenic lahko uporabite tudi preprosto za izdelavo drevesnih avtomobilov in iger, kot so uganke. S različnimi velikostmi ravnih steklenic lahko ustvarite različne velikosti lukov ali edinstvene sloga za vaše projekte. Če ustvarjate drevesne predmete z robovi, kot so slike v okvirjih in ogledala, bodo ravnih steklenic pomagale ustvariti lepe robe, da vse izgleda težje in profesionalneje.

Popolna upravljanja zahteva material in močne logistične sisteme, verigo ponudnikov ravnih pumpek ter trdno logistično podlago. Izvozi v več kot 60 držav in služi več kot 2000 strank po vsem svetu.

Uradniki za uvožene CNC orodja, glavne strojne opreme; pripomočki strojev; Aljuzinski rezni pripomoček; merilna orodja; naprave; številčno kontrolirana orodja Merilna oprema pogosto uporabljana v ravnih pumpek, letalski sektor, natančna izdelava moldov, avtomobilski sektor, CNC proizvodnja.

Podjetja pridržujejo profesionalno etiko "čestna in zaupanja vredna", stroga dela ob uporabi ravne bitov, ki služijo uporabnikom z polnim storitvami, odvisno od masovnega logističnega skladiščnega sistema, ki vključuje obsežen zalog, neposredni nakup, da se zagotovi autentičnost izdelka iz prvoročnih virov.

Xuzhou Huazhichun CNC Technology Co., Ltd., Specializirana prodaja uvoženih CNC orodij, strojilskih merilnih orodij, dodatkov za modele, ravnih bitov, več. Izdelki: Uvožena in domača natančna rezanja, merjenje, testiranje, dodatki za modele orodij.