Alat pemotong CNC ialah mesin khusus yang digunakan dalam pelbagai perdagangan. Alat ini membantu dalam memotong, membentuk, dan membentuk logam, kayu dan plastik. Alat ini penting kerana ia memudahkan dan mempercepatkan kerja. Tetapi kita mesti berhati-hati kerana menggunakan mesin ini boleh membahayakan alam sekitar dalam pelbagai cara. Hari ini kita akan membincangkan pendekatan yang lebih mesra alam untuk menggunakan alat pemotong CNC. The Huazhichun, sangat mengambil berat tentang Bumi dan mempunyai beberapa nasihat yang bagus untuk menggunakan alat ini dengan cara yang lebih mesra alam.

Pemilihan Alat Pemotong CNC yang mesra alam:

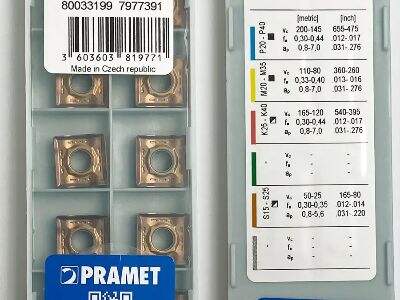

Perbezaan Alam Sekitar dengan Alat Pemotong CNC yang Betul Beberapa alat terbaik untuk dipertimbangkan ialah karbida dan seramik yang diperbuat daripada bahan yang kuat. Ini Alat CNC adalah ideal kerana ia tahan lama dan menghasilkan kurang bahan buangan daripada bahan lain. Kami percaya dalam menggunakan pengeluaran pintar dan hijau untuk mencipta produk kami di Huazhichun. Kami juga suka menggunakan bahan kitar semula kerana ia mengurangkan pencemaran dan menjadikan dunia ini bersih. Kita semua boleh menyumbang kepada perlindungan alam sekitar dengan memilih pilihan mesra alam

Kesan Alam Sekitar Alat Pemotong CNC:

Alat pemotong CNC sangat membantu, juga berbahaya kepada alam sekitar. Alat ini boleh mengeluarkan bahan kimia berbahaya dan habuk ke udara apabila ia digunakan. Ini boleh memudaratkan kesihatan orang dan haiwan berdekatan. Alat ini meninggalkan sisa terkumpul di tapak pelupusan sampah dan merosakkan planet kita. Selain itu, tenaga elektrik yang digunakan oleh mesin ini menyumbang kepada pencemaran dan gas rumah hijau. Huazhichun sentiasa berusaha untuk mengurangkan kerosakan yang boleh disebabkan oleh alat pemotong CNC kami. Ini dicapai dengan mematuhi peraturan keselamatan dengan ketat, mengitar semula sisa apabila boleh. Inilah cara kami boleh membantu mengekalkan Bumi yang lebih bersih.

Kelebihan Alat Pemotong CNC:

Walaupun kelemahannya, alat pemotong CNC juga mempunyai banyak kelebihan yang mungkin menjadikannya berbaloi untuk digunakan. Mereka adalah alat yang sangat ketepatan seperti sisipan karbida berbenang yang boleh dipotong menjadi bentuk yang sangat tepat. Bukan sahaja ia berfungsi dengan lebih pantas, malah ia juga lebih cekap, sekali gus menjimatkan masa dan tenaga. Mereka juga memerlukan sedikit bantuan manusia, yang memastikan proses kerja lebih lancar. Lebih-lebih lagi, teknologi baharu telah membolehkan penyediaan reka bentuk dengan sisa yang lebih sedikit, yang penting untuk kemampanan. Alat pemotong CNC Huazhichun adalah cekap dan menggunakan sejumlah kecil tenaga dan menjana sisa yang minimum

Cara Menggunakan Alat Pemotong CNC Dengan Cara Mesra Alam

Memastikan bahawa sisipan karbida persegi pelaksanaan alat pemotong CNC adalah mampan memerlukan kita mengawinkan penggunaannya dengan proses pembuatan pintar dan amalan kerja yang selamat. Berikut adalah beberapa petua berguna untuk diikuti:

Pilih Bahan Mesra Alam: Untuk bilah pemotong CNC, pilih bahan yang diperbuat daripada bahan mesra alam yang mampan alam sekitar.

Penyelenggaraan Alat Secara Tetap: Sentiasa menyelenggara dan melincirkan alatan supaya ia tidak menghasilkan lebih banyak sisa dan tenaga buangan apabila ia berjalan.

Pilih Pembersih Biodata: Secara amnya, tidak digalakkan menggunakan pelarut toksik semasa membersihkan mesin. Ia membantu menjadikan alam sekitar selamat serta mengitar semula sisa yang mereka hasilkan.

Kepentingan sama ada pengendali perlu diajar tentang penggunaan alatan yang selamat dan ekologi – Operator Kereta Api Latihan dalam pengurusan sebarang sisa berbahaya yang dijana semasa operasi juga sangat penting.

Think About You Designs: Cari alternatif kepada reka bentuk anda yang boleh membantu anda mengurangkan pembaziran bahan. Ini akan menyebabkan pembaziran berkurangan dan penggunaan sumber yang lebih cekap.

Alat Pemotong CNC CNC: Cara Mengurangkan Kesan Memudaratkan kepada Alam Sekitar

kita boleh melihat beberapa langkah nyata yang boleh diikuti oleh pengeluar untuk menambah baik cara alat pemotong CNC mereka mempengaruhi planet ini. Berikut adalah beberapa langkah yang kukuh:

Kurangkan Penggunaan Tenaga: Dengan menggunakan komponen, pemasangan dan kawalan mesin yang memerlukan kurang tenaga, adalah mungkin untuk mengurangkan penggunaan tenaga secara besar-besaran.

Kitar Semula dan Bahan Boleh Digunakan Semula: Sangat penting untuk mengumpul dan mengitar semula cip, cecair pemotongan dan penyejuk dsb. Jika anda menjumpai sebarang bahan berbahaya seperti bilah, sebaiknya kitar semula bahan tersebut di tempat ia boleh dilupuskan dengan selamat oleh pengilang khusus.

Gunakan Proses Pengilangan Mampan: Sesuaikan proses yang akan membelai pengasingan daripada pelbagai bahan mentah untuk mengurangkan sisa yang dihasilkan.

Kurangkan Sisa Toksik: Kaedah pembuatan mesra alam tidak mengeluarkan bahan kimia toksik ke udara dan penting dalam memelihara planet kita.

Kami berharap artikel ini dapat membantu anda mengetahui amalan terbaik untuk mengendalikan alat pemotong CNC dengan cara yang mesra alam. Dengan keputusan yang bijak dan petua ini, kita semua boleh bergerak ke arah persekitaran yang lebih sihat. Ini pernah dan masih, dalam banyak kes halangan teknikal yang agak tinggi. Dengan alat pemotong CNC kami sedia ada, kami percaya kami boleh meminimumkan jejak alam sekitar kami sambil menyumbang kepada komuniti tempat kami beroperasi

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

TIDAK

TIDAK

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

KA

KA

UR

UR

BN

BN