Les machines peuvent produire de nombreux types de formes différentes. Ce processus est réalisé à l'aide de l'usinage CNC. CNC est l'abréviation de Computer Numerical Control. Cela signifie que les machines CNC exécutent des programmes informatiques pour contrôler le mouvement des machines-outils. Cela leur permet de fournir une découpe, un façonnage et un perçage hautement contrôlés du métal, du plastique, du bois, etc.

Que sont les porte-outils CNC ?

Les porte-outils CNC sont des composants clés du processus d'usinage CNC. Ils fonctionnent comme les mains de la machine, maintenant fermement les outils de coupe en place. Ces outils peuvent être des forets, des fraises, des tarauds ou des alésoirs. Le porte-outil garantit que les outils restent stables et droits pendant le fonctionnement. Si le porte-outil n'est pas adapté à la tâche, la machine ne peut pas maintenir l'outil correctement.

Sélection du bon porte-outil

Ce blog identifie pourquoi choisir le bon porte-outil CNC ainsi que outil de coupe pour tour à commande numérique a un impact sur les performances d'usinage CNC. Le bon porte-outil peut permettre à la machine de fonctionner mieux, plus rapidement et avec plus de précision. Vous pouvez utiliser différents types de porte-outils, et chacun d'eux possède ses propres caractéristiques uniques, ce qui permet de prendre en charge des travaux de différentes tailles.

Quels sont les différents types de porte-outils CNC

Il y a plusieurs choses à garder à l'esprit lors du choix d'un porte-outil CNC chez Huazhichun série pour outils cncVous devez tenir compte du type d’outil avec lequel vous travaillez, des dimensions et de la forme de l’outil, du matériau que vous coupez et de la finition que vous souhaitez créer sur la surface.

Porte-outil à pince : un porte-outil à pince utilise un composant à ressort qui maintient fermement les outils ronds. Il est excellent pour stabiliser le processus de coupe.

Porte-outil hydraulique : ce support utilise du fluide hydraulique pour serrer l'outil en toute sécurité et améliorer les performances de coupe.

Porte-outil à ajustement rétréci : cela se fait en refroidissant le porte-outil réel et en chauffant l'outil lui-même pour qu'il s'adapte parfaitement au support.

Porte-outil à visser : ce type utilise une connexion filetée pour maintenir fermement en place les outils de plus grand diamètre.

Mandrin de fraisage : il est utilisé pour maintenir les fraises et autres fraises.

Porte-outil à douille : ce type permet de convertir la broche de la machine en outils plus petits pour une machine adaptable afin d'effectuer davantage de tâches.

Pourquoi les porte-outils sont importants

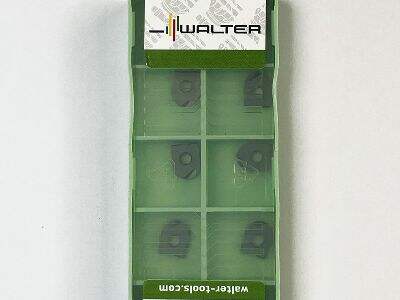

Porte-outils CNC ainsi que insert cnc Les fraises ne sont pas des éléments de moindre importance, mais elles font partie intégrante du processus d'usinage CNC. Elles aident les machines à faire leur travail, permettant l'introduction d'une multitude d'outils différents. Elles permettent aux machines de sculpter des formes et des motifs complexes avec précision.

Impact des porte-outils sur la qualité et le coût

La qualité et le coût de fabrication des produits avec des machines CNC dépendent fortement des performances du porte-outil. Si un porte-outil ne fonctionne pas correctement, cela peut entraîner la rupture des outils, une usure incorrecte ou la création de défauts de surface sur les composants fabriqués.

Enfin, les porte-outils CNC sont un élément important de l'usinage CNC. Ils sont essentiels pour une fabrication de haute qualité, efficace et rentable.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NON

NON

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

KA

KA

UR

UR

BN

BN