Pokud ano, použili jste někdy karbídové vrtací šroubováky ? Pokud ne, chybí vám úžasný nástroj! Právě proto mohou být vaše osobní ostří vyrobeny z karbidu, protože je to typ charakteristiky specifické pro tyto nástroje, které jsou užitečné při řezání materiálů právě tehdy, když jste zapojeni do svých dřevěných projektů. V tomto článku si probereme různé důvody, proč jsou karbidová ostří extrémně výhodná a jak dokážou splnit úkoly s neuvěřitelnou snadností a přesností pro uživatele.

Ostruhová pila je složena z velmi tvrdého a odolného materiálu známého jako ostruha. Jejím základem je speciální sloučenina vytvořená mícháním uhlíku s dalšími prvky. Ostruha je také velmi silná, proto je ideální pro řezání tvrdých a náročných materiálů. Použitím ostruhového ostří dosáhnete čistších řezů při řezání. To znamená, že bude méně roztrhaných okrajů nebo škrábanců na vašich řezech. Ostruhové ostří jsou extrémně trvanlivé, což je další skvělá věc. Životnost dobré kosy je dlouhá a potřebují pouze občasné zaostřování a nahrazování. To znamená, že si můžete ušetřit čas i peníze, protože nebude nutné kupovat nová ostří velmi často!

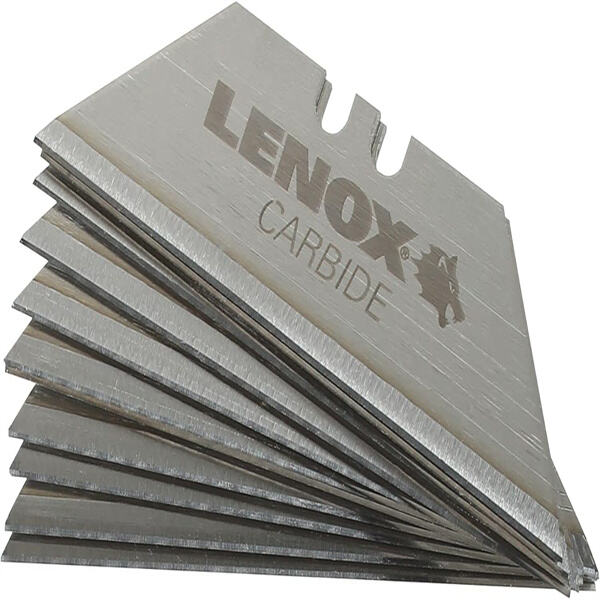

Karbidové čepele jsou ideální pro každodenní úkoly, protože jsou velmi univerzální. Dokážou řezat různé materiály! Karbidové čepele například dokážou proříznout dřevo, kov, plast a dokonce i kámen nebo cihlové konstrukce. To je opravdu užitečné, protože nemusíte nosit různé čepele pro různé materiály. Sbohem ručním ohýbačům, protože teď potřebujete jen jednu. čepel karbidová to to udělat vše! Listy z karbidu se také dodávají v různých typech zubů, takže můžete zvolit ten správný pro danou práci. Tento rozsah vám dává možnost vybrat si správný nástroj pro úkol.

List z karbidu může být hroudacím faktorem při dřevozpracovných projektech. Tyto listy jsou známé pro svou vysokou přesnost, což znamená, že jsou schopny provádět velmi přesné řezy. Ať už řezáte rovně nebo ve křivce, karbidový list prolomí snadno. Je to zejména důležité při vytváření pěkného nábytku či skříní. Navíc karbidové listy mohou pracovat na několika druzích dřeva, ať už jde o tvrdé nebo měkké dřevo. To znamená, že je můžete použít pro různé druhy dřevozpracovných projektů, od jednoduchých řemesel po složitější výrobu nábytku.

V podstatě existují dva typy čepů při řezání: Čepeče z tvrdého kovu a čepeče z rychlořezavé oceli. Čepeče z rychlořezavé oceli jsou trvanlivé a vydržují dlouho, ale nejsou tak tvrdé na jemnou strukturu jako čepeče z tvrdého kovu. To může vést ke zušlechťování čepečů z rychlořezavé oceli, které je třeba ostrhat nebo nahradit poměrně často. Naopak čepeče z tvrdého kovu jsou tvrdé a vyžadují méně ostrahu než ocelové čepeče. To je dělá preferovanými pro práce, které vyžadují jak přesnost, tak i trvanlivost. Čepeče z tvrdého kovu jsou určitě stojící za to, pokud chcete zajistit, aby byly vaše řezy čisté a přesné.

Při výběru karbidového ostří je třeba mít na paměti několik klíčových faktorů. To vám pomůže vybrat nejlepší konstrukci zubu podle vašich potřeb. Za druhé, vezměte v úvahu tloušťku materiálu, který budete řezat. To by mělo vést k výběru ostří s příslušnou tloušťkou. Nakonec zvažte velikost ostří. Musíte zajistit, aby jste vybrali ostří, které odpovídá velikosti vašeho řezacího nástroje, aby fungovalo správně a bezpečně.

Xuzhou Huazhichun CNC Technology Co., Ltd., Profesionální karbidové čepele, dovážené CNC nástrojové kovy, měřicí nástroje, doplňky, elektrické nástroje a mnoho dalšího. Produkty: Všechny druhy dovážené a domácí přesné měřicí nástroje, řezací nástroje, testovací zařízení, doplňky k formům.

Dovozní CNC nástroje tvoří hlavní vybavení, jakožto příslušenství strojních nástrojů, jako jsou slitové řezací nástroje, měřicí nástroje, karbidové čepele ovládacích nástrojů, přístroje.

Spoléháme se na rozsáhlé logistické skladové systémy, které přímé karbidové čepele dodávají z původního místa, zaručují autenticitu produktu.

Vynikající logistika, pevná správa dodavatelského řetězce, bezchybná správa požadovaného materiálu. Poskytuje více než 2000 karbidových čepelí po celém světě a exportuje do více než 60 zemí.