هل سبق لك أن سمعت عن آلة CNC؟ إنها نوع خاص من الآلات التي يمكن استخدامها لقطع وتشكيل مجموعة واسعة من المواد بما في ذلك الخشب والمعادن وحتى بعض أنواع البلاستيك. يمكنك التعامل معها كروبوت يمكنه القيام بالأعمال الشاقة نيابة عنك! يمكن أن تكون قوية للغاية وتساعدك في بناء جميع أنواع الأشياء. ولكن ماذا لو أخبرتك أنه يمكنك ترقية آلة CNC الخاصة بك للعمل بكفاءة أكبر مما تعمل به بالفعل؟ يستلزم هذا تحديد مسارات الأدوات المناسبة التي تستخدمها الآلة لقص المواد.

ما هي مسارات الأدوات؟

أفضل مسارات الأدوات هي تلك التي تصف الطريقة الأكثر ذكاءً التي ستقطع بها ماكينة CNC المواد التي ستعمل عليها. عندما تقوم بتحسين أو إدخال تحسينات على مسارات الأدوات هذه، ستنتهي بشكل أسرع، وهذا سيوفر لك المال ويتطلب استخدامًا أقل للمواد. بهذه الطريقة، فإنك تقلل أيضًا من النفايات وبالتالي تساعد البيئة. ماذا عن مسارات الأدوات المحسنة، دعنا نتعرف عليها أكثر.

التفاصيل الكاملة حول مسارات الأدوات الأفضل

هناك العديد من الفوائد لاستخدام مسارات الأدوات المحسنة لآلة CNC الخاصة بك. تتمثل إحدى نقاط البيع الأساسية في أنها يمكن أن تساعدك على العمل بشكل أسرع بشكل ملحوظ. مع مسارات الأدوات اللائقة، يمكن لآلتك أداء مهمتها بسرعة وكفاءة مما يعني بدوره أنك تصل إلى الجزء الخاص بك بشكل أسرع. هذا أمر رائع إذا كان لديك الكثير من المشاريع لإكمالها.

من بين الفوائد الضخمة الأخرى أنه يمكن أن يوفر لك المال. من خلال تشغيل آلتك بشكل أفضل وأكثر كفاءة، ستهدر مواد أقل. وهذا يعني أنك تنفق أموالاً أقل على اللوازم، وهو أمر جيد دائمًا. كما أنه يساعد البيئة من خلال تقليل النفايات، وهو أمر يجب أن نهتم به جميعًا، من خلال استخدام مواد أقل.

يمكن أن تؤدي مسارات الأدوات المحسنة أيضًا إلى جعل القطع تبدو أجمل وأكثر عملية. إن استخدام مسار الأداة المناسب لآلتك والمادة المحددة يمنحك قطعًا أكثر سلاسة ودقة. كل هذا يمكن أن يقودك إلى إنشاء منتجات جديدة ومحسنة سيحبها عملاؤك ويقدرونها.

مسارات أدوات جيدة لتسهيل عملية القطع باستخدام الحاسب الآلي

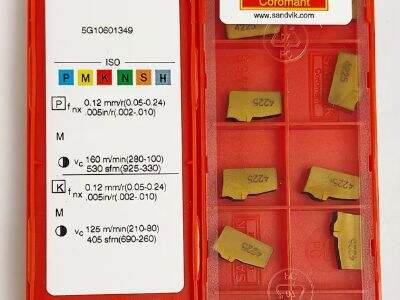

للاستفادة من مسارات الأدوات الأفضل، يجب أن يكون لديك الأدوات المناسبة بالإضافة إلى بعض المعلومات التي ترشدك إلى المنزل. ومن الأمثلة الجيدة جدًا على ذلك برنامج CAM حتى أكتوبر 2023 CAM → التصنيع بمساعدة الكمبيوتر → يعمل هذا النوع من البرامج معك لإنشاء أفضل مسار ممكن للأدوات لآلتك والمواد التي تعمل بها. يمكنك تحسين أداء آلتك بشكل كبير.

ولكن امتلاك البرنامج يعني عدم امتلاك أي شيء، ويجب عليك أيضًا معرفة كيفية استخدام هذه الأداة بشكل فعال. وهذا يعني تعلم طرق بديلة للقطع، مثل القطع المتسلق والقطع التقليدي. إن فهم طريقة القطع التي ستسفر عن أفضل النتائج أمر ضروري لنجاح المشروع. تأتي كل طريقة مع إيجابياتها وسلبياتها، لذا يجب عليك الاختيار بعناية.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

لا

لا

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

MK

MK

KA

KA

UR

UR

BN

BN